Looking at 12 months worth of electricity bills gives a good starting point for understanding how much power gets used on average, when consumption spikes happen throughout the day, and how weather affects overall usage from month to month. Also think ahead about what might change in the next few years, like getting an electric car charged at home or adding another room to the house. Getting the right size system means finding that sweet spot between regular battery drain and having enough juice stored away for blackouts. Systems that are too big just cost extra money without any real benefit, but ones that are too small end up relying too heavily on the main power grid whenever there's even a minor disruption.

Professional installers assess key structural and electrical factors before installation:

Regulatory compliance spans three levels:

| Jurisdiction Level | Common Requirements | Typical Timelines |

|---|---|---|

| Local Municipal | Building permits, Fire safety clearance | 2–4 weeks |

| Utility Provider | Interconnection agreements, Meter upgrades | 4–8 weeks |

| State/Federal | Incentive program compliance, NEC Article 705 adherence | Varies |

| Experienced installers manage documentation and ensure adherence to NEC 2023 standards, including clear working space and emergency disconnect placement. |

For household solar battery safety, getting UL 9540 certification is pretty much essential when looking at fire resistance and preventing those dangerous thermal runaways we all want to avoid. Companies such as Intertek step in here to check if products actually follow standards like IEC 62619 regarding electrical shocks and how well enclosures hold up over time. When shopping around, look for batteries equipped with built-in fault detection systems. These smart features will cut power connections automatically whenever there are voltage issues, which cuts down on arc flash dangers significantly. Some studies show this tech reduces risk by about two thirds versus standard models according to recent findings from NFPA back in 2023.

According to NREL research from 2023, about 41% of problems with home solar batteries actually come down to bad grounding issues. When checking these systems, techs need to look closely at the terminals where aluminum meets copper because those spots tend to corrode over time. Also important is keeping at least three feet away from anything that might catch fire. Don't go overboard connecting multiple batteries together past what the maker recommends, and watch out for wires that are too small since both situations can cause serious overheating problems. Using infrared cameras when testing under load is pretty smart too. This lets technicians spot potential trouble areas long before turning on the whole system.

When working on installations, certified professionals need to wear proper protective gear according to OSHA standards. That means getting those 1000 volt insulated gloves with leather protectors, plus face shields rated at least 40 calories per square centimeter against arcs. Anyone doing work on rooftops should also have fall arrest equipment ready just in case. Lockout tagout procedures aren't optional either they're absolutely necessary when servicing systems. These protocols help disconnect battery banks from both photovoltaic arrays and grid connections safely. And don't forget daily hazard assessments either these checklists can save lives. Every worksite needs emergency kits too, specifically ones containing Class C fire extinguishers designed for fighting lithium ion battery fires which happen more often than we'd like to admit.

Lithium ion batteries perform optimally when kept at consistent temps around 10 to 30 degrees Celsius according to Energy.gov's 2023 report. Putting them inside where there's some climate control works well, especially in places like garages or utility rooms that follow the latest fire safety standards outlined in PAS 63100:2024. When installing outside, make sure they're protected against sun damage and harsh weather conditions with proper enclosures designed for whatever extreme temperatures are common locally. Don't think about putting these in attics, under houses, or anywhere prone to flooding though. Bad location choices actually shorten battery life pretty significantly, sometimes cutting capacity down by as much as 18 percent over time as noted by NREL studies from 2023.

For lithium ion systems, getting enough airflow is critical to prevent dangerous overheating. The general rule of thumb is about half to one cubic meter per minute of air movement for every kilowatt of system capacity. When it comes to safety standards, the 2023 National Electrical Code now demands at least 30 centimeters of free space on all sides around battery enclosures, plus special ventilation for lead acid units. Installers working near the coast face extra challenges from saltwater damage. That's why specifiers should look for nickel plated busbars that resist corrosion and enclosures rated NEMA 4X, which provide protection against harsh marine conditions where regular equipment would quickly fail.

| Factor | NEC Requirement | Performance Impact |

|---|---|---|

| Conductor size | ≤ 125% of max current | Limits voltage drop to <3% |

| Conduit fill capacity | ≤ 40% for 2+ conductors | Reduces overheating risk |

| Grounding | 6 AWG copper minimum | Prevents stray voltage buildup |

Use NEC Article 706 tables to size conductors and torque-limiting tools for terminal connections—overtightening accounts for 23% of early battery failures (NFPA 2023). Apply anti-oxidant gel to aluminum conductors to maintain long-term conductivity.

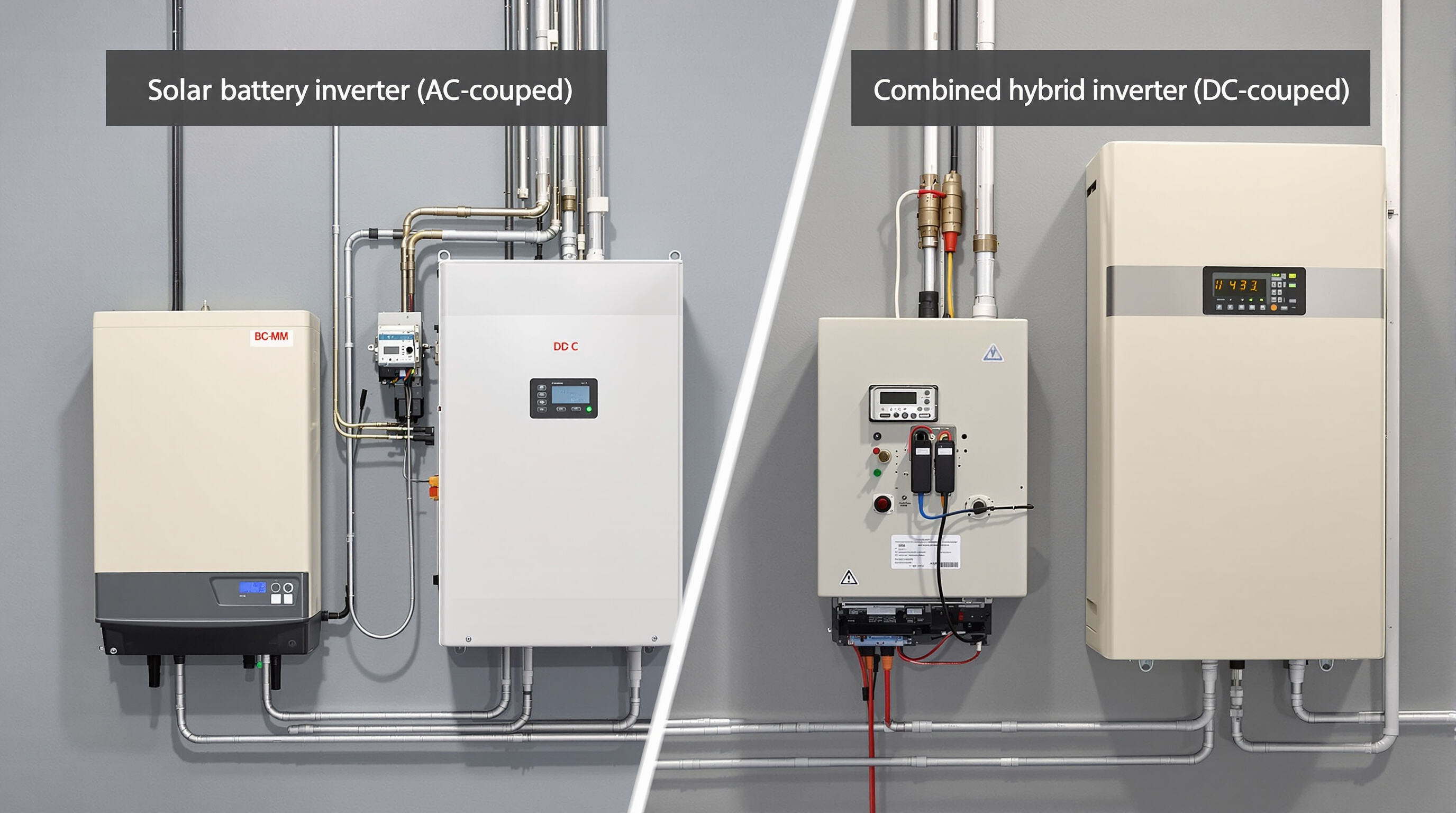

AC coupled systems work with separate inverters for the solar panels and batteries, which makes them good for adding batteries to older solar setups. But there's a catch they lose around 10 to maybe even 15 percent efficiency because of all those extra steps converting energy back and forth. On the other hand, DC coupled systems only need one inverter shared between everything. This setup can hit almost 98 percent efficiency since it cuts down on those conversions so much. A recent study from early 2024 showed something interesting too these DC systems actually cut hardware expenses by about 18 percent when installing something brand new. The downside? They need special hybrid inverters that can handle both the solar panels and the battery storage together, which adds another layer of compatibility requirements for installers to consider.

Make sure the inverter specs line up with what the battery needs in terms of voltage and chemical makeup otherwise things might get too hot or lose their ability to hold power properly. When working with AC coupled setups, always check if the grid tied inverters have proper anti islanding features built in so there's no dangerous electricity going back into the grid when there's an outage somewhere. For those DC coupled systems, nobody gets around needing a NEC 690 certified charge controller these days just to keep everything flowing correctly through the system. And don't forget about ground fault protection either way we go since lithium ion batteries tend to spark problems between 20 and 50 volts DC which nobody wants happening especially not狷疗ly while someone is nearby.

Back in 2022, there was this fire incident down in Texas where someone had installed a solar system wrong. Turns out the problem came from mixing incompatible parts - specifically some mismatched inverters paired with LFP batteries in what's called a DC coupled setup. What actually started it all? An uncertified charge controller got way too hot when discharging at maximum capacity. Fast forward to 2024 and another study shows something pretty alarming: about seven out of ten residential battery fires are linked to do-it-yourself installations missing proper UL 9540 certification. That kind of thing just wouldn't happen if people went through certified professionals for their installations instead.

Testing systems properly ensures they work well and stay safe. When installing equipment, technicians need to check how batteries charge and discharge by running them through approved load banks from manufacturers to see if they actually hold their rated capacity according to NREL findings from 2023. Ground faults are really important to catch early because these hidden electrical leaks were behind nearly a quarter of all home fires related to solar installations just last year per NFPA data. Sure, many battery management systems now handle most tests automatically, but there's still no substitute for old fashioned hands-on checking of things like insulation resistance levels and whether those circuit breakers trip when they should.

The commissioning process typically involves running a 72 hour stress test on the batteries, cycling them from fully charged down to about 20% discharge level. This helps spot any voltage issues that might not show up during normal operation. For checking wiring problems, infrared cameras are really useful because they can find those hot spots where energy tends to leak away, especially in systems that weren't installed properly. Once everything is set up, it's a good idea for homeowners to check out monitoring tools such as SolarLog or EnergyHub. Keeping an eye on round trip efficiency makes sense too. Most lithium ion batteries should maintain around 92% efficiency or better over time if everything works correctly.

Installers who have earned their NABCEP certification go through around 58 hours of specialized battery training plus complete 10 installations under supervision. This rigorous process cuts down on mistakes significantly, with error rates dropping by roughly 81% when compared to those without proper certification according to IREC research from 2023. When shopping for solar services, look for companies that provide at least a decade long warranty that covers not just the equipment itself but also the workmanship involved. Such comprehensive coverage handles about 94% of problems that pop up after installation without charging homeowners extra money, per Clean Energy Reviews findings last year. Don't forget to check if the contractor carries insurance that specifically covers errors and omissions (often abbreviated as E&O). This kind of protection becomes crucial when there are slip ups in design plans or permitting requirements get overlooked during the project.

Before installing solar batteries, consider your energy consumption needs, any expected changes in your household's energy use, and the proper sizing of the battery system. Evaluate the structural and electrical factors of your home for safety and compliance.

Regulatory compliance ensures your solar battery installation adheres to local, utility, and state/federal requirements, avoiding potential legal issues and ensuring safety throughout the system's operation.

Safety measures include using certified batteries, identifying potential fire and electrical hazards, ensuring personal protective gear is used, and adhering to specific installation protocols such as lockout tagout procedures.

AC-coupled systems use separate inverters for solar panels and batteries, suitable for retrofitting older systems. DC-coupled systems share one inverter, offering higher efficiency but requiring compatible hybrid inverters.

Look for installers with NABCEP certification, which ensures advanced training and reduced error rates. Check for comprehensive warranties and liability insurance to cover potential mistakes during installation.